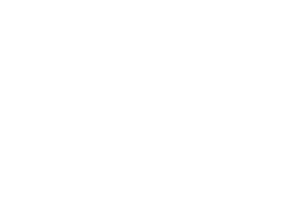

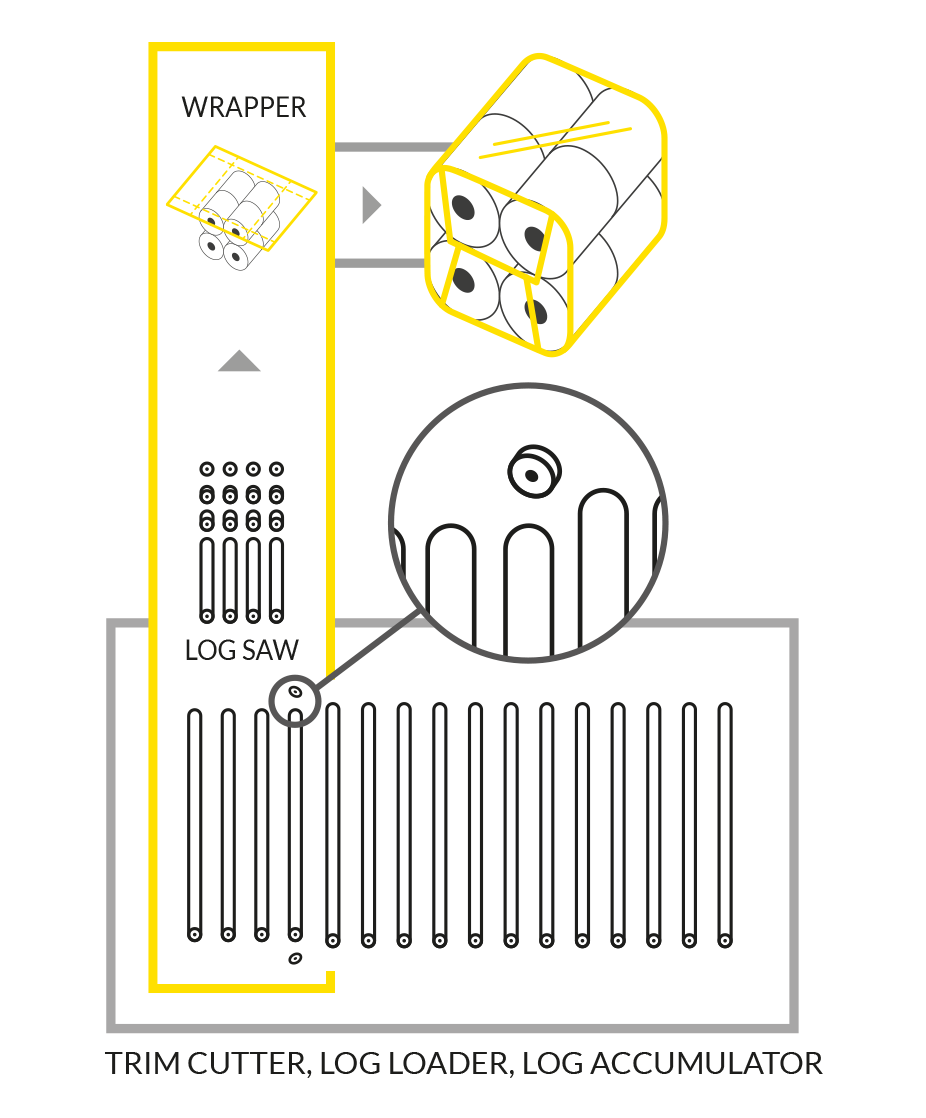

FROM LOG TO PACK IN ONE COMPACT MACHINE.

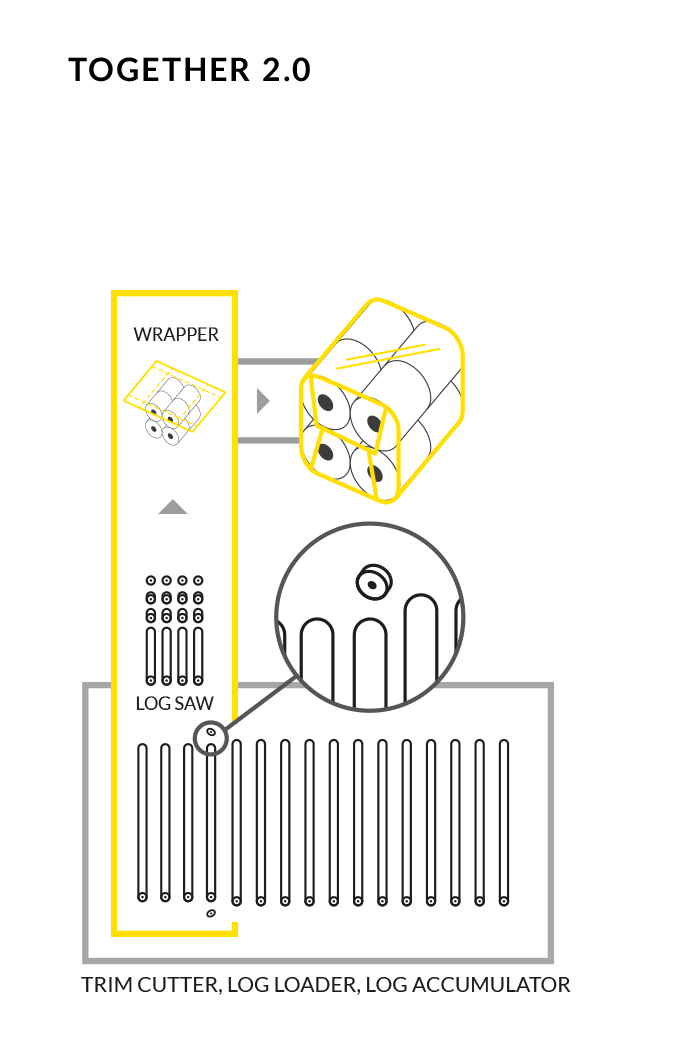

Together 2.0 trims, cuts and packages, redrawing the boundaries between rewinding and packaging. From the log to shelf-ready pack: for anyone considering a new line here is the opportunity to take a different approach and benefit from a series of advantages which were previously unthinkable.

Together 2.0 includes an integrated Trim Cut with absolute cutting precision for reduced trim thickness (as little as 15 mm per side) and a consequent reduction in waste. In addition, 100% of trim is removed at the accumulator rather than the log saw, which prevents trims reaching the end of the line, eliminating the risk of blockages and product damage.

A log saw with a new automatic blade change and sharpening system that eliminates manual operations, improves safety standards and guarantees greater blade life.

A fully automatic, compact packaging machine which easily reaches 220ppm and allows a format change in just 7 minutes, guaranteeing performance, hygiene and absolute quality of packaging, with better folds, sealing and closure for a more well preserved and safer product.

PROCESS OPTIMIZATION

The innovations introduced allow the line to reach superior integrated performance combined with optimum productivity.

BETTER PRODUCT FLOW

OPTIMIZED WRAPPING CYCLE

CONTINUOUS MOTION

HIGHER PERFORMANCE

Shortening the line and eliminating conveyors and choke belts guarantees a level of production continuity never seen before. It also means a substantial increase in speed which automatically increases packaging speed, with no operator intervention required and no risk of blockages.

MAXIMUM SPEED IN PRODUCTION: 220 PPM

FAST FORMAT CHANGE-OVER: 10 MINUTES

UNIQUE SPEED SETTINGS

CONSTANT AND HOMOGENEOUS PRODUCT FLOW

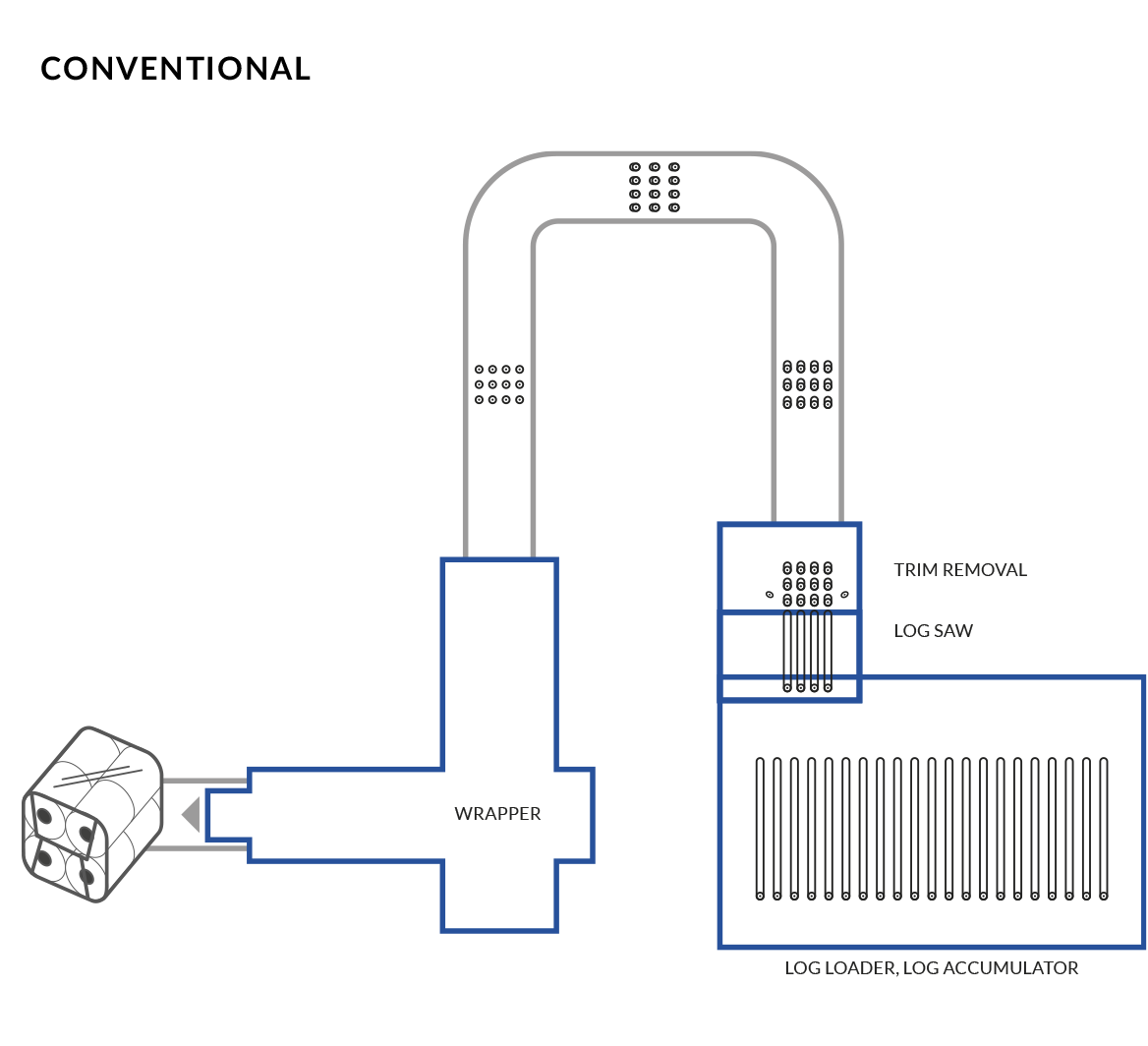

SPACE OPTIMIZATION

The integration of Together in a Converting line will allow tissue producers to optimize the use of space. The compact layout of Together brings a drastic reduction in footprint, with up to 300 sq m saved for each line which also allows more lines in the same premises.

COMPACT LAYOUT

NO CHOKE BELTS

NO LINK CONVEYORS

ABSOLUTE SIMPLIFICATION

Thanks to the reduction in components and the simplification of the production line, Together also makes management and maintenance of the line easier, reduces the consumption of energy and the number of operators required.

UNIQUE CONTROL PANEL

UNIQUE SOFTWARE

SINGLE OPERATOR

TWO SIZES OF SERVOMOTOR ONLY

TWO GEAR MODELS ONLY

SHORTER PRODUCTION LINE

ZERO DOWNTIME OR ACCUMULATION

PRODUCT QUALITY

The shorter production line, the fact that it is enclosed and the lack of choke belts guarantees a continuous flow of product with no deformation, and at higher speeds.

Better folds, and a sealed and closed pack for a product which is more hygienic and better protected.

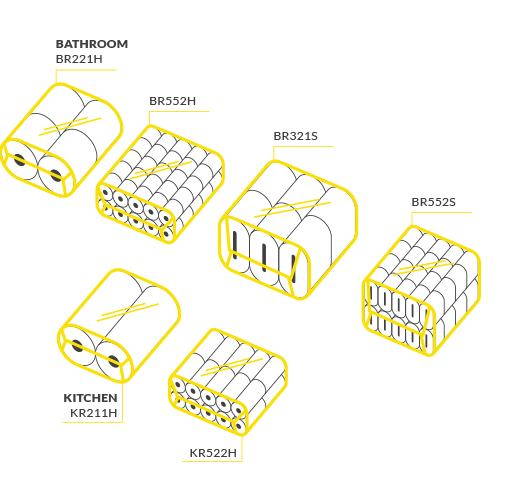

MACHINE CAPACITY RANGE: B111H/B563H

ROLL DIMENSION RANGE:

D 90/160MM (OPTIONAL 200MM); L 90/300MM

PACK DIMENSION RANGE:

W 100/600MM, L 100/600MM, H 90/380MM

POLYETHYLENE CUTTING RANGE:

MAX L 1050 W 1750; REEL DIAMETER UP TO 600MM

MORE SAFETY

The simplification and shortening of the line, the reduction in the number of components, the durability and strength of the materials used, and the better accessibility of the installation make operation and maintenance far easier and guarantee absolute safety to operators.

MAXIMUM DURABILITY

FULL ACCESSIBILITY

SIMPLIFIED OPERATION AND MAINTENANCE